6HH1

Showing 1–24 of 39 results

-

-

-

-

-

-

-

-

-

-

-

-

6HE1, 6HH1

Gasket Cylinder Head For Isuzu FSR Encava 6HH1 8.2L 6HE1 7.1L 95-14 New Oem

OEM Cylinder Head Gasket for Isuzu FSR Encava engines — compatible with 6HH1 8.2L and 6HE1 7.1L models (1995–2014). Designed for perfect sealing, high combustion resistance, and long-lasting durability during engine rebuilds or repairs.

SKU: IEK-583 -

6HH1

Gasket Exhaust Manifold To Head | Isuzu 6HH1 / FVR Engine

Premium Exhaust Manifold to Head Gasket designed for Isuzu 6HH1 FVR diesel engines. Ensures a tight, leak-free seal between the cylinder head and exhaust manifold for improved performance and durability under high temperatures.

SKU: IEK-686 -

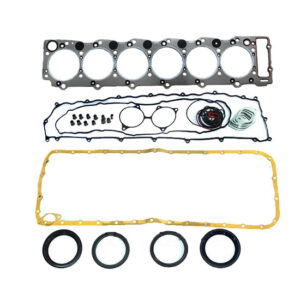

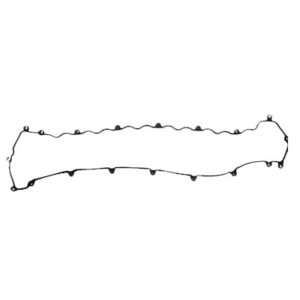

6HE1, 6HH1

Gasket Head To Cover | Isuzu 6HH1 / 6HE1 / FTR FVR FSR FRR

High-quality Head to Cover Gasket designed for Isuzu 6HH1 / 6HE1 diesel engines. Provides a leak-proof seal between the valve cover and cylinder head, keeping your engine oil-tight and clean under heavy-duty operation.

SKU: IEK-680 -

-

-

-

-

6HH1

Oil Pan Gasket | Isuzu 6HH1 Engine | 2000-2014

High-quality Oil Pan Gasket for Isuzu 6HH1 Engine (2000–2014) — precision-engineered for perfect sealing and leak prevention. Fits Isuzu FVR, FSR, and FRR trucks. Made with premium heat-resistant materials to deliver long-term durability and reliable oil containment.

SKU: IEK-661

Isuzu 6HH1 Engine Rebuild Kits & Replacement Parts

The Isuzu 6HH1 diesel engine is a heavy‑duty inline‑six known for strong torque, long service intervals, and dependable operation in demanding fleets. As mileage and hours accumulate, wear to rings, liners, bearings, and sealing surfaces can reduce compression, raise oil consumption, and increase smoke. A correctly matched 6HH1 engine rebuild kit restores sealing integrity, recovers power, and returns your vehicle or machine to predictable uptime—without dealer‑level costs. All components offered here are curated specifically for the 6HH1 platform and manufactured to meet or exceed OEM specifications, so you can rebuild once and rebuild right.

Complete 6HH1 Overhaul Solutions

- Full / Upper / Lower Gasket Sets: Precision‑cut materials engineered to contain combustion, coolant, and oil under thermal load and vibration.

- Pistons, Rings & Pins: Tight tolerance control and optimized ring tension to recover compression, reduce blow‑by, and stabilize oil use.

- Cylinder Liners: Semi‑finished or finished liners to re‑establish true bore geometry for cleaner combustion and durability.

- Main & Rod Bearings: Load‑bearing shells built to spec for smooth crank rotation, pressure stability, and long journal life.

- Thrust Washers: Proper crankshaft end‑play control to protect thrust faces during axial loading.

- Valve‑Train Components (select kits): Guides, seals, and seats to improve top‑end stability and reduce seepage.

Each kit is assembled to suit common Isuzu 6HH1 service scenarios, minimizing parts chasing and installation delays.

Typical 6HH1 Applications

The 6HH1 powers medium‑ and heavy‑duty trucks, buses, vocational chassis, and industrial equipment. These duty cycles require steady low‑RPM torque, reliable cold starts, and long service intervals—capabilities sustained by a precise rebuild using accurately matched components.

When an Overhaul Makes Sense

- Hard Starts / Low Compression: Worn rings or scored liners reduce cranking pressure and cold‑start reliability.

- Rising Oil Consumption: Glazed bores or tired ring packs pull oil past the rings, increasing smoke and operating cost.

- Blue/White/Black Smoke: Indicates sealing, fueling, or oil‑control imbalance; a top/bottom‑end refresh often resolves it.

- Knocking or Tapping: Bearing wear or piston slap requires inspection before further operation.

- Coolant/Oil Cross‑Contamination: Aging head‑gasket or stack sealing may require a comprehensive reseal.

- Loss of Power / Poor Fuel Economy: Compression recovery via pistons/liners and a full reseal can restore efficiency.

Fitment & Sizing Guidance

Confirm these points before ordering to ensure correct fit and long service life:

- Engine Identification: Verify 6HH1 model, variant, and emission configuration from the engine tag or service documentation.

- Liner Type & Target Bore: Determine semi‑finished vs. finished liners and confirm final bore size and protrusion spec.

- Piston/Ring Specifications: Match compression height, crown style, and ring pack dimensions to your build sheet.

- Bearing Grades: Check main/rod bearing sizes (STD or undersize) against measured crank journal diameters.

- Associated Components: Consider oil pump, water pump, and timing components if service history is unknown.

Installer Notes & Best Practices

- Measure Everything: Mic crank pins/journals; verify liner protrusion and piston‑to‑wall clearances per spec.

- Surface Prep: Deck and head must be flat, clean, and residue‑free; follow torque sequence and angle specs precisely.

- Cleanliness: Flush oil galleries, clean ring lands, and keep assembly areas lint‑free to prevent premature wear.

- Lubrication: Use assembly lube where specified; pre‑lube bearings and prime the oiling system before first start.

- Fuel & Air System Checks: After mechanical overhaul, verify injector condition, pump calibration, and boost tract integrity.

- Break‑In: Use proper break‑in procedures and oil to seat rings quickly and stabilize blow‑by.

Performance & Uptime Benefits

- Compression Recovery: Correct pistons/liners restore cranking pressure, throttle response, and hill‑climb performance.

- Leak & Smoke Reduction: New gaskets, seals, and ring packs reduce weeps, blow‑by, and visible exhaust smoke.

- Lower Operating Cost: Improved oil control and combustion efficiency help manage fuel and maintenance spend.

- Predictable Service Intervals: Fresh wear components reset maintenance timelines for planned uptime.

Ordering Made Simple

- Identify: Confirm 6HH1 model and any variant/update details on your engine tag or manual.

- Select: Choose a full overhaul kit or targeted top/bottom‑end sets and components.

- Verify: Match piston/liner sizes and bearing grades to measured dimensions before checkout.

- Install: Follow torque and angle specifications; observe best practices for cleanliness and lubrication.